HIFOUNE reach truck adopts scissor fork telescopic mechanism to realize the pick-up and placement of single/double-deep pallet racks, and achieves the maximum forward distance with the smallest channel size. It not only greatly improves the utilization rate of shelf space, but also can flexibly deal with side-by-side racks, reduce the number of warehouse aisles, and increase the storage density of goods by 200%.

This forklift has excellent lifting capacity, strong bearing capacity, excellent high-position stability, and wide-view mast design, which makes it suitable for narrow channel operations, warehouses, large supermarkets and workshops. It is an ideal tool for loading and unloading stacking, meeting the customized needs of various usage scenarios, and the operation is safe and comfortable.

MFE series scissor fork reach truck classification

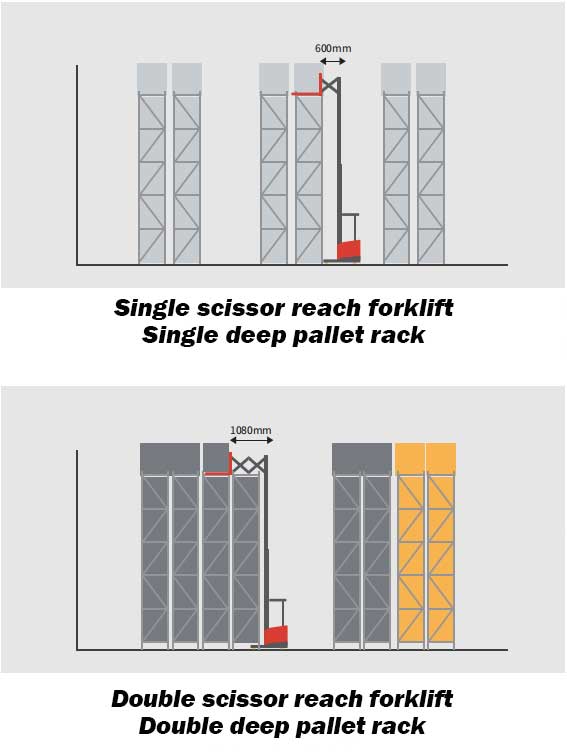

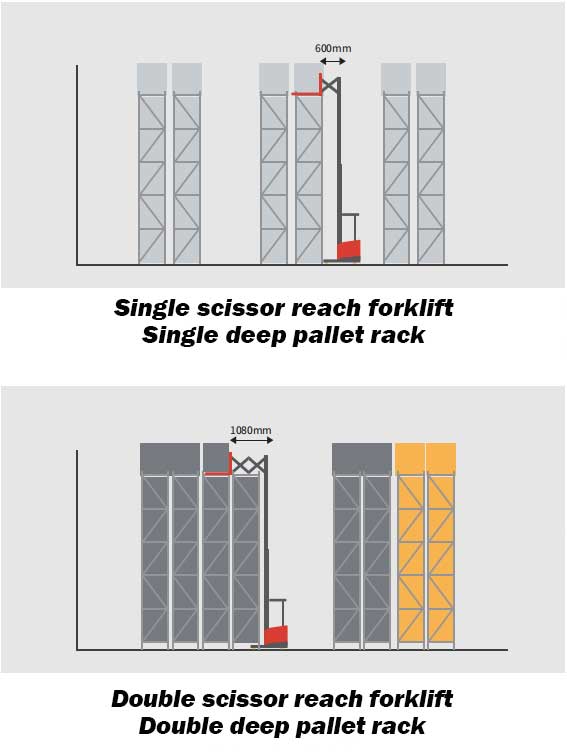

HIFOUNE scissor fork reach truck is divided into two categories: single scissor fork and double scissor fork, each with its own advantages to meet the needs of different storage scenarios.

01 Single Scissor Fork (Single-Deep Scissor Fork)

HIFOUNE single scissor fork reach truck, rated load 2 tons, fork reach distance 600mm, lifting height up to 10160mm, suitable for single-deep pallet rack, showing excellent adaptability and efficiency.

02 Double Scissor Fork (Double-Deep Scissor Fork)

HIFOUNE

double scissor fork reach truck, rated load 1.4 tons, fork reach distance 1080mm, maximum lifting height is also 10160mm. Suitable for double-deep pallet rack, not only improves the stability of cargo stacking, but also significantly improves the storage capacity rate.

Product Highlights

1. Scissor fork design: HIFOUNE scissor fork reach truck is equipped with scissor fork telescopic mechanism, which can realize scissor fork telescopic, side shifting, tilting, and relatively complete cargo picking and placing functions.

2. Excellent vision: wide-view mast design, unobstructed vision, creating a broad and clear visual space for the operator. Combined with dual cameras to assist operation, and through the split-screen display of the monitor, the location of the goods is clear at a glance, providing a strong guarantee for precise operation.

3. Safe and stable: The high-precision gantry is used to ensure that there is no loss of load below 8 meters, and the ultra-high load capacity is also excellent. Equipped with advanced limit, automatic sensing speed limit and buffering functions to avoid impact, achieve dual protection of goods and ground, and improve the safety of warehousing operations.

4. Comfortable operation: The integrated handle design is adopted to achieve a dual improvement in linkage operation fluency and control accuracy. Lowering the height of the forklift pedal from the ground makes it more convenient for the operator to get on the vehicle, significantly enhancing the comfort of operation.

5. Energy-saving and efficient: The full AC maintenance-free system, with built-in speed sensor and temperature sensor, accurately monitors the operating status, is energy-saving and efficient, has high reliability and long life. It has a faster lifting speed, lowering speed and driving speed, which greatly improves the operating efficiency.